Un laboratorio in divenire per l’innovazione nella gestione dei sistemi acquedottistici/An “in becoming” space for innovation in pipe system management

Gran parte delle attività svolte presso il WEL sono rese possibili grazie al sistema di alimentazione e ricircolo, che comprende un serbatoio in pressione (fino a 16 bar), 5 pompe, un serbatoio di accumulo e oltre 1500 metri di tubazioni, articolate in diversi sistemi: tubi in polietilene (DN 110, DN 90, DN 50 e DN 32), tubi in ghisa sferoidale (DN 100 e DN 80) e tubi in rame (DN 20).

Most of the activity at the WEL are carried out thanks to the supply and recycling system, including a pressurized tank (up to 16 bar), 5 pumps, a storage tank, and more than 1500 m of pipes, articulated in different systems (polyethylene pipes, DN 110, DN 90, DN 50 and DN32; cast iron pipes, DN100 and DN80; copper pipes, DN20).

I primissimi anni in laboratorio/The very first years in the lab

The former “very long” pipe just built

While building the support for the “very long” pipe

The former “very long” pipe just built

The former “very long” pipe just built

The former “very long” pipe with the “short” pipe on the backgroud

While building the support for both the former pipes

The former pumping group

The structural design of the metallic cover of the recycling tank

The structural design of the metallic cover of the recycling tank

Branches of pipe just arrived from the seller

The former “very long” pipe just built

I primi anni 2000/The early 2000s

The coiled copper pipe

The channel

A view of the laboratory

The Portable Pressure Wave Maker (PPWM) device

Recenti potenziamenti/Recent upgrades

Feb. 2015 – The lab status

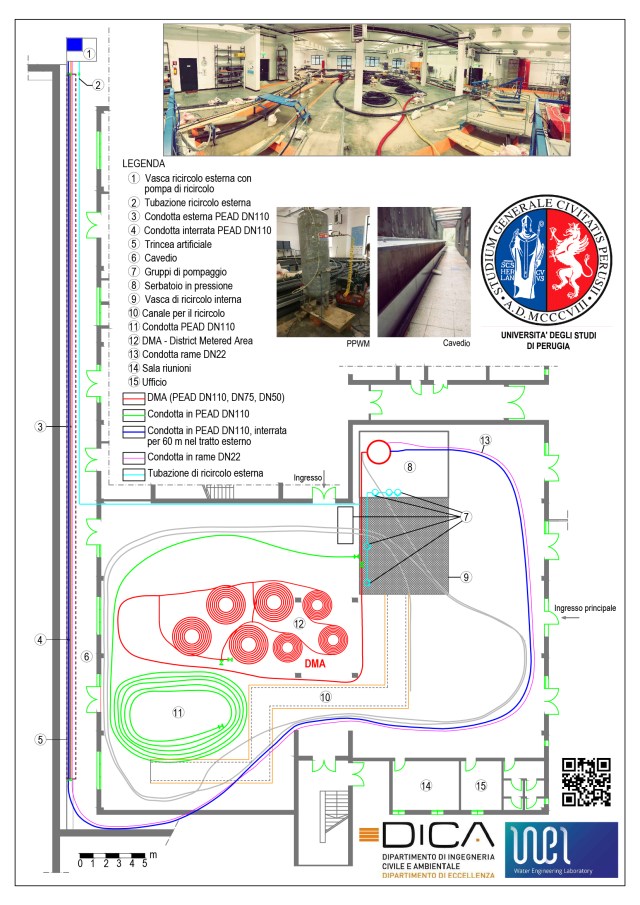

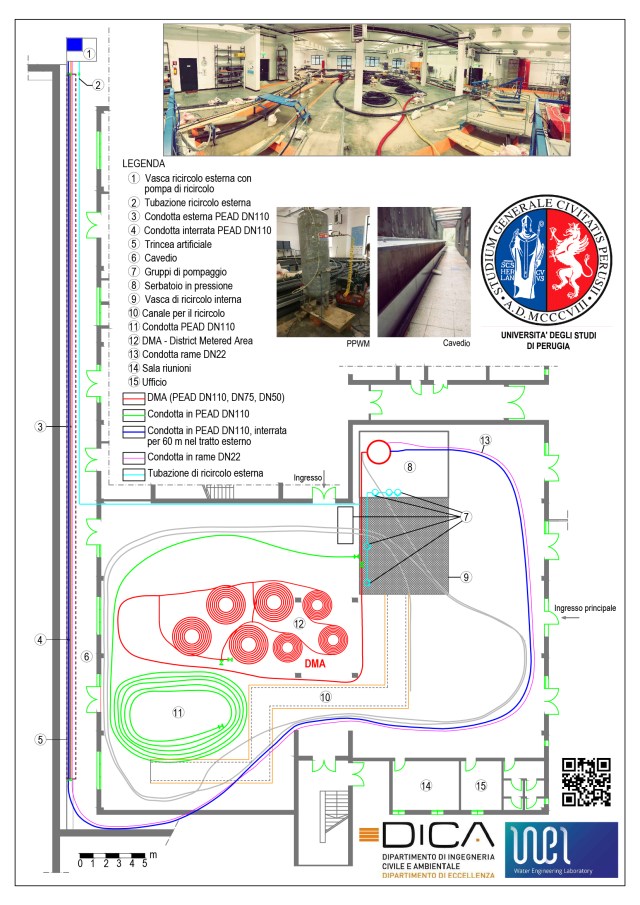

Feb. 2015 – Planimetry of the WEL

June 2017 – Small diameter copper and polyethylene pipes are installed

June 2018 – Rolls of pipes with different diameters are introduced in the lab to build a network

Dec. 2018 – One polyethylene pipe is dismantled

I più recenti potenziamenti/Latest upgrades

Jan. 2019 – Two loops-network is installed

June 2019 – Small diameter copper and polyethylene pipes are moved on the other side and a new workstation is installed

The current planimetry of the WEL

The outside: before the renovation

The outside: after the renovation – straight pipes, buried and unburied, are installed

The current state of the WEL